Home

Gofar provides our customer one-stop shop for their injection molding needs. We can provide product design drawings, build your prototypes and manufacture your molds. We also have the complete capabilities to produce your parts, decorate them, custom assemble and package them, and ship your finished product to your factory. Our team is committed to satisfying your needs.

Capabilities

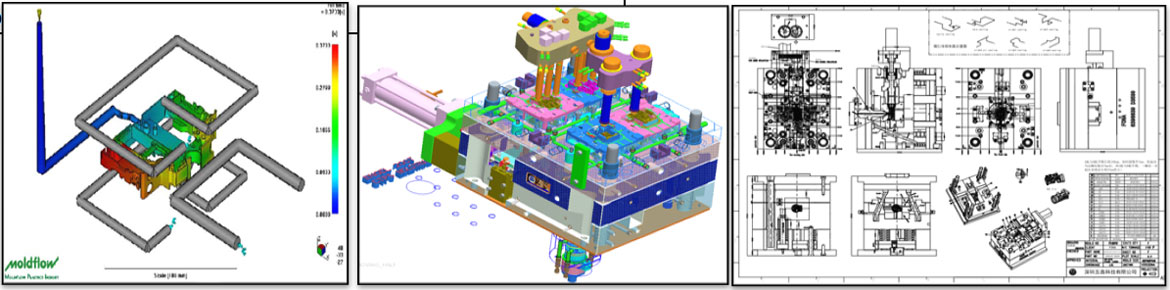

Design Engineering

Gofar offers full engineering services for part and product development. We can analyze your component design, applying our "Design for Manufacture" expertise to maximize mouldability, minimize second operations, reduce assembly times and simplify tooling - adding value at every stage.

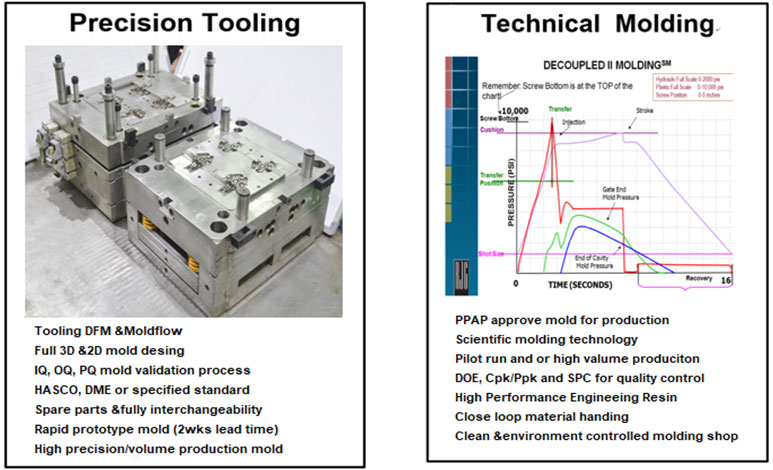

Tooling Making

①.SPI class 101,hot runner, full automation production mold. ②.Automotive, mold size up to 1.2 meter and 10 ton. ③.Medical, Printers, High precision mold. ④.High Performance/ Temperature Engineering plastic mold. ⑤.2K mold.

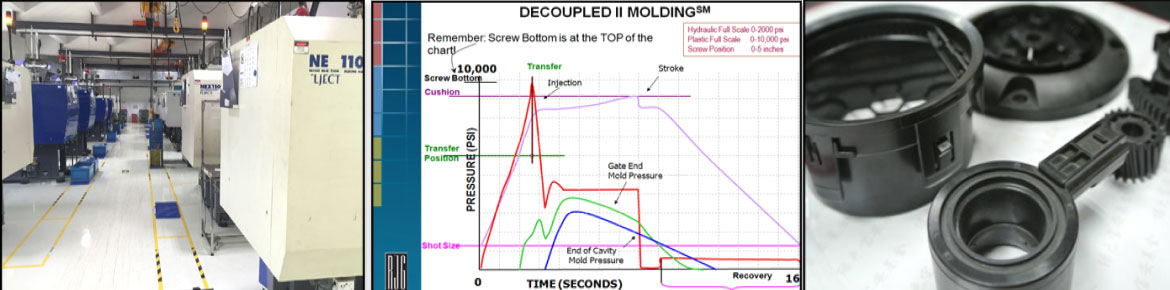

Injection molding

We use the Scientific De-coupled Molding Technology and Molding parameters DOE (Design of Experiments) to identify the optimum molding parameters and process window checking.

Value-Added Services

Gofar Not Just a Mouldmaker! ①.3D printing, Vacuum casting or CNC prototyping ②.Rubber parts ③.Metal stamping &die casting ④.Painting, Plating & printing ⑤.Assembly &Custom packaging

Quality Assurance

TS16949 certificated company. PPAP approval mold for production. We keep continuous improvement on our product, process and customer service.

Project Management

English speaking Engineer, Keep one contact window. We offer our customer a complete and efficient project management team.