Injection molding

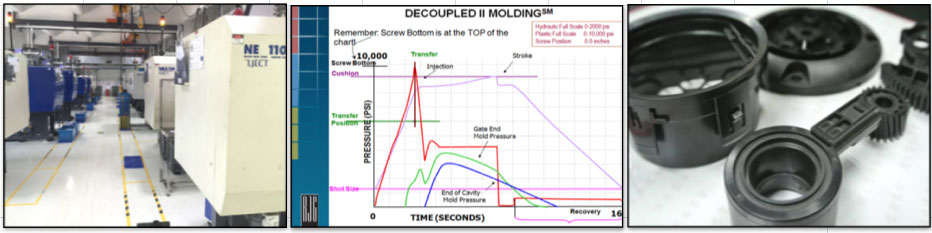

We use the Scientific De-coupled Molding Technology and Molding parameters DOE (Design of Experiments) to identify the optimum molding parameters and process window checking.

We focus on high precision engineering parts, tight tolerance parts molding. We process a full range of commodity and engineering grade thermoplastics on modern injection equipment with environment controlled molding shop. Closed-loop controls and robotics guarantee part to part consistency.

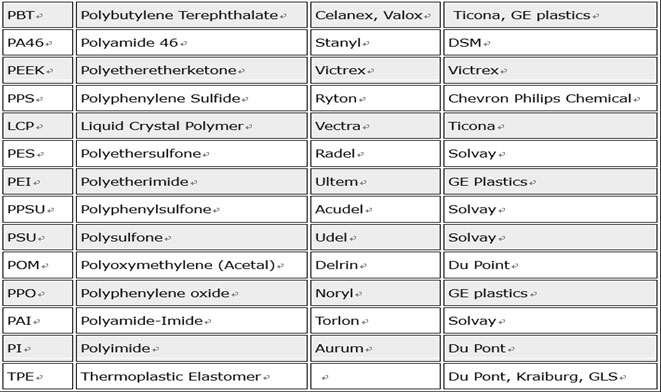

Here are some of the more specialized materials we work with:

We have 30 injection moulding machines, ranging in size from 50 to 350 tonnes, providing us with the flexibility, we need to meet our customers’ individual requirements. Our automatic injection moulding machinery are far more efficient for medium to large run production, both in terms of reducing component costs and increasing productivity. Running 24 hours a day, they allow for ultra fast turnaround from order to delivery. We can also offer stocking programs to insure that you always have the molded plastic parts you need, when you need them.

Every product receives a 2-hour in-process inspection. Every 2 hours during production, parts are pulled for a visual inspection and key areas are measure for accuracy.

With our in-house tooling department we can maintain, change and repair tooling in-house without the need to outsource.